|

|

Petroleum and Chemical Consulting and Modeling for Enhanced Oil Recovery |

|---|---|---|

Houston, TX - Phone: (281) 564 - 8851 |

||

Miscible Gas Displacements |

|||

|

Often gas injection is called miscible or immiscible. This section illustrates important aspects of a miscible displacement of Wasson oil at reservoir conditions. The photographs are from microvisual experiments conducted at Shell Development Company in 1984. |

||

Miscible Three Phase Displacement at 1,350 psig (9.38 Mpa) Pressure |

|||

|

|||

|

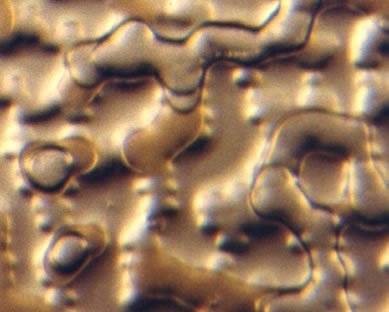

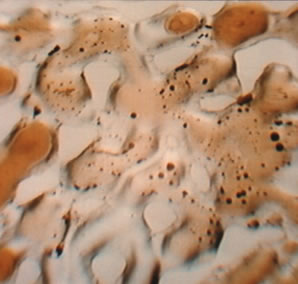

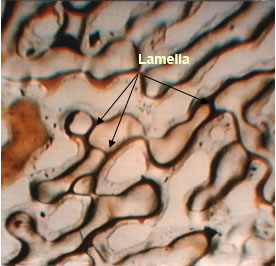

The next photograph shows a fully developed miscible displacement at 2,000 psig (13.90 Mpa). The photograph shows a light colored band of oil (highlighted with an arrow in the direction of the flow) that is fingering through darker, bypassed oil. What has happened at this pressure is that the CO2 has become so enriched in C3 to C10 hydrocarbons that it is totally miscible with the oil. The enriched phase has liquid densities, so all fluids are called liquids. With continued injection, the concentration of light hydrocarbons in the miscible phase decreases. Then, the fluid is no longer miscible with the oil and the “lower-liquid, ” a heavy, asphaltene-like phase begins to precipitate. This is shown in the third photograph. The dark dots are the lower-liquid (oil). This phase continues to precipitate and eventually its saturation is high enough that the fluid spreads between the CO2 and water as shown in the fourth figure. However, the lower liquid also wets the surface of the microvisual model so that foam lamella (indicated again by arrows) form. This phenomenon is known as gas-oil foam and may be responsible for the injectivity reduction reported in projects like Wasson. |

||

Developed Miscible Displacement |

|||

|

|||

Later In Developed Miscible Displacement |

Very Late in a Miscible Displacement |

||

|

|

||

|

|||